Have you ever wondered how products stay fresh and secure on store shelves? The answer lies in the sealing process, and one of the most effective methods is induction heat sealing.

In this post, you’ll learn why induction heat sealing is essential for keeping products fresh, safe, and appealing to consumers.

What is Induction Heat Sealing?

Induction heat sealing is a non-contact method of bonding thermoplastic materials using electromagnetic induction. It creates a secure, airtight seal that safeguards product integrity.

So, how does it work? Let's break it down:

Components of an Induction Seal

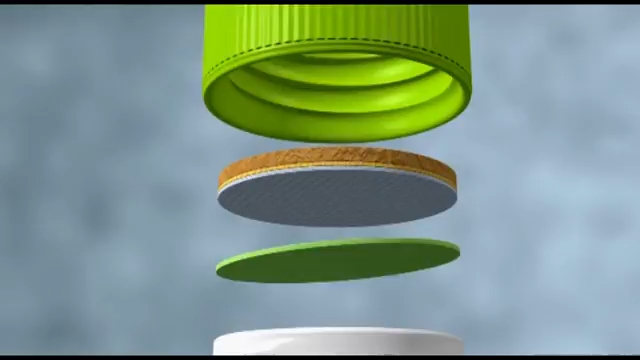

An induction seal consists of several layers:

Aluminum foil: Heats up when exposed to electromagnetic field

Wax: Binds the foil to the plastic film

Plastic film: Seals the container opening

Polymer: Ensures a strong bond between foil and container

The Sealing Process

The seal is placed inside the container cap

The capped container passes under an induction coil

The coil generates an electromagnetic field

This field heats the aluminum foil

The wax melts, releasing the foil from the cap

The plastic film bonds with the container, creating an airtight seal

Induction sealing is widely used across industries, including:

Food and beverage

Pharmaceuticals

Cosmetics

Chemicals

Advantages of Induction Heat Sealing

Induction heat sealing offers a multitude of benefits that make it a top choice for packaging. Let's explore these advantages in detail:

Enhanced Product Freshness and Extended Shelf Life

One of the primary benefits of induction sealing is its ability to extend product shelf life. The airtight seal it creates prevents contamination from external elements like air, moisture, and bacteria. This seal locks in freshness and preserves product quality for longer periods compared to other sealing methods.

Tamper-Evidence and Improved Safety

Induction seals provide visible evidence of tampering, ensuring product integrity. If someone attempts to open the package, the seal will be visibly disturbed or broken. This tamper-evident feature boosts consumer confidence in the product's safety and authenticity.

Increased Efficiency and Productivity

Induction sealing is a high-speed process that can seal a wide range of container sizes and materials. This efficiency enables businesses to streamline their packaging operations and increase productivity. Whether you're sealing plastic, glass, or metal containers, induction sealing can handle it all.

Customization and Versatility

Induction seals offer customization options that can elevate your packaging. You can print QR codes, promotional materials, or product information directly on the seal. This versatility allows you to enhance your brand's visibility and engage with customers in new ways.

Sustainability and Eco-Friendliness

Induction sealing is an eco-friendly choice for packaging. It reduces waste compared to other sealing methods by using minimal materials. Additionally, many induction seals are made from recyclable materials, further contributing to sustainability efforts.

Embracing induction heat sealing can revolutionize your packaging process. Its numerous advantages make it a smart investment for businesses looking to improve product quality, safety, and efficiency while minimizing environmental impact.

Induction Heat Sealing vs. Other Sealing Methods

When choosing a sealing method for your packaging, it's crucial to consider the advantages and disadvantages of each option. Let's compare induction heat sealing with two common alternatives: conduction sealing and shrink wrapping.

Comparison with Conduction Sealing

Conduction sealing involves direct contact between the sealing machine and the container. In contrast, induction sealing is a non-contact method. This difference gives induction sealing several advantages:

Improved hygiene: The non-contact nature of induction sealing minimizes the risk of contamination during the sealing process.

Increased efficiency: Induction sealing can seal containers without stopping the packaging line, resulting in faster production speeds.

Cost-effectiveness: Induction sealing machines can accommodate a wide range of container sizes, reducing the need for multiple machines and saving costs.

Comparison with Shrink Wrapping

Shrink wrapping is another popular sealing method, but it has some drawbacks compared to induction sealing:

Packaging material: Shrink wrapping requires more packaging material to completely encase the container, while induction sealing only needs a small seal on the opening.

Sealing speed: Induction sealing is typically faster than shrink wrapping, as it can be done on a continuous conveyor belt without stopping.

Equipment footprint: Induction sealing machines often require less space than shrink wrapping equipment, making them a more space-efficient choice for packaging lines.

When evaluating sealing methods, consider factors like product safety, production efficiency, and environmental impact. In many cases, induction heat sealing emerges as the superior choice due to its hygiene, speed, and versatility advantages.

Frequently Asked Questions

How does induction heat sealing affect product shelf life?

Induction heat sealing creates an airtight barrier that prevents oxygen, moisture, and other contaminants from entering the container. This seal helps maintain product freshness and extends shelf life significantly compared to unsealed or poorly sealed containers.

Can induction heat sealing be used with all types of containers?

Induction sealing is versatile and can be used with a wide range of container materials, including plastic, glass, and metal. However, some containers may require pre-treatment or special considerations:

Plastic containers with plastic caps are the easiest to seal

Glass containers may need to be treated before sealing

Metal containers can be sealed, but the metal cap may become hot during the process

Is induction heat sealing safe for food products?

Yes, induction heat sealing is safe for food products. The sealing process does not involve any direct contact with the product, minimizing the risk of contamination. Additionally, the materials used in induction seals are typically food-grade and FDA-approved.

How does induction heat sealing contribute to sustainability efforts?

Induction sealing is an eco-friendly packaging solution. It uses minimal packaging materials compared to other methods like shrink wrapping. Many induction seals are made from recyclable materials, further reducing waste. The extended product shelf life also helps reduce food waste.

What industries benefit the most from using induction heat sealing?

Induction heat sealing is widely used across various industries, but some sectors benefit more than others:

Food and beverage: Extends shelf life and prevents leaks

Pharmaceuticals: Ensures product safety and tamper-evidence

Cosmetics: Maintains product quality and freshness

Chemicals: Prevents spills and contamination during transport and storage

Conclusion

Induction heat sealing offers numerous benefits, including extended shelf life, tamper-evidence, and enhanced product safety. It’s also efficient and eco-friendly, making it a top choice for various industries. Choosing the right sealing equipment is crucial to ensure your products are well-protected. By selecting the proper tools and process, you can maximize these benefits, keeping your products fresh and secure while also contributing to sustainability.