Have you ever wondered how cosmetic companies ensure the quality and functionality of their lotion pumps? Lotion pumps play a crucial role in the packaging of various cosmetic products, from moisturizers to shampoos. With different types of pumps available, such as screw-type, card-type, and foam pumps, it's essential to conduct thorough functional testing to guarantee optimal performance.

In this article, we'll explore the significance of functional testing for cosmetic lotion pumps and delve into the various test methods employed to assess their effectiveness.

What are Cosmetic Lotion Pumps?

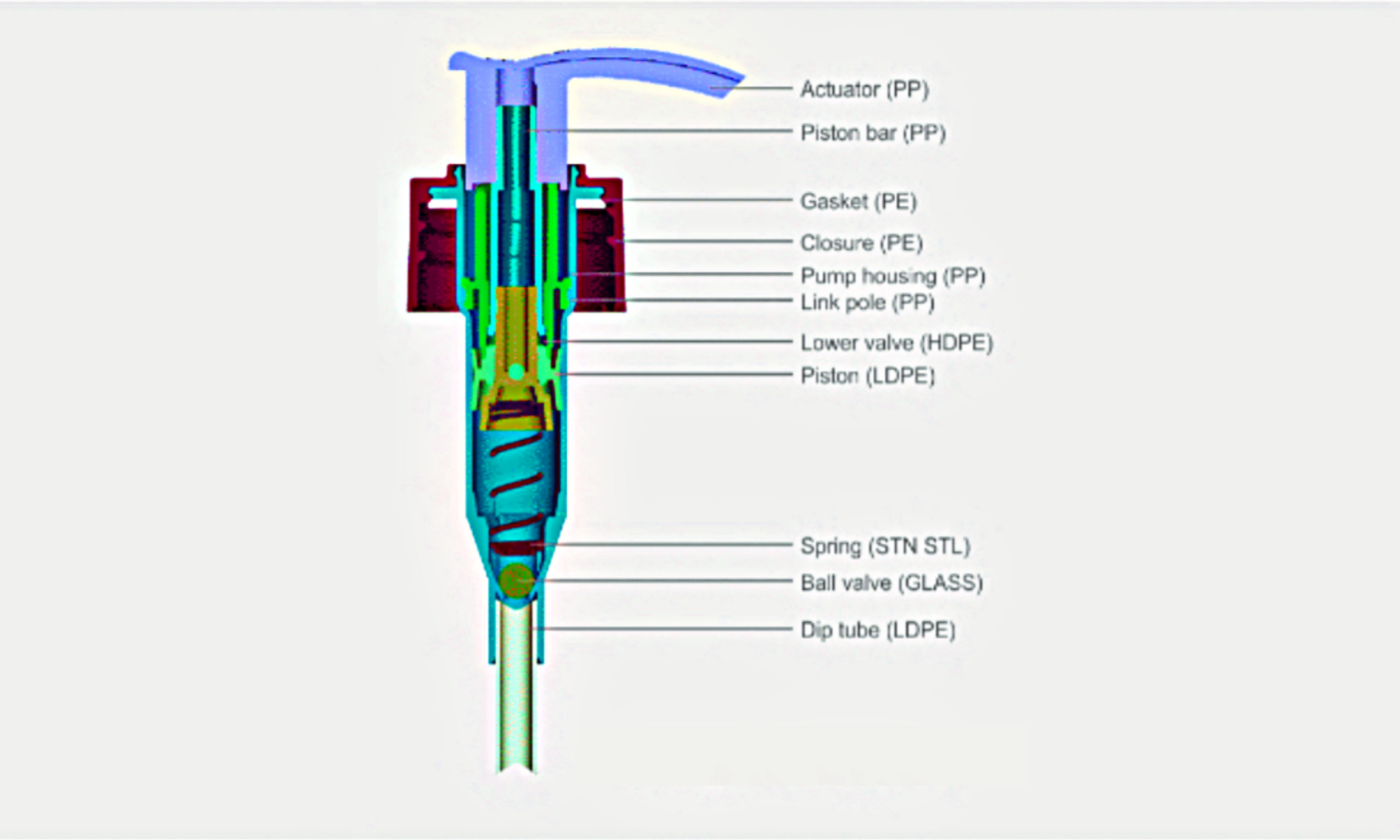

Lotion pumps are essential components in cosmetic packaging. They dispense a controlled amount of product, such as lotions, creams, or shampoos, with each press of the pump head. Lotion pumps provide a convenient and hygienic way to access the product without exposing the entire contents to air or contamination.

Different types of lotion pumps

There are several types of lotion pumps, each with its unique features:

Screw type pump: It has a threaded collar that screws onto the bottle neck for a secure fit.

Card type pump: This type uses a plastic card to lock the pump in place on the bottle neck.

Left and right lock pump: It features a locking mechanism that secures the pump by turning it left or right.

Hand buckle type pump (spray gun): This pump resembles a spray gun and is commonly used for products like cleaning solutions.

Direct push type pump with outer cover: It has a protective outer cover and dispenses product when the pump head is pressed down.

Functional types

Lotion pumps come in various functional types, each with its own working principle:

Lotion pump principle: A basic reciprocating piston pump that dispenses product when the pump head is pressed and released.

Vacuum pump principle: It uses a vacuum system to draw the product up from the bottle without a dip tube.

Foam pump principle: This type mixes the product with air to create a foamy texture when dispensed.

Spray pump (spray head) principle: It uses a nozzle to atomize the product into a fine mist when the pump head is pressed.

Aerosol pump principle: This type uses compressed gas to dispense the product as an aerosol spray.

Foam Pump

Lotion Pump

Acrylic Pump

| Pump Type | Locking Mechanism | Dispensing Method |

| Screw type pump | Threaded collar | Press and release |

| Card type pump | Plastic card | Press and release |

| Left and right lock pump | Turning lock | Press and release |

| Hand buckle type pump (spray gun) | Buckle or clip | Trigger press |

| Direct push type pump with outer cover | Outer cover | Press down |

Factors Affecting the Pumping Effect of Lotion Pumps

Tightness of the Glass (Steel) Ball Under the Spring

The tightness of the glass or steel ball affects how the pump works. If it's too loose, lotion may leak back into the bottle. This reduces the amount dispensed with each press. On the other hand, if it's too tight, the lotion won't flow smoothly.

Tightness of the Sealing Ring at the Upper End of the Valve Body

The sealing ring's tightness is crucial. If the ring is not tight enough, air can seep in. This causes inconsistent lotion flow. A proper seal ensures that each press delivers the right amount.

Proper Sealing Ring Tightness: Ensures no air leaks

Loose Sealing Ring: Causes air to enter, leading to uneven dispensing

| Issue | Cause | Solution |

| Lotion leakage | Loose glass/steel ball | Adjust ball tightness |

| Inconsistent flow | Loose sealing ring | Ensure proper seal |

| Reduced dispensing | Over-tight glass/steel ball | Adjust to correct tightness |

Detailed Functional Test Methods

Material Inspection

Using high-quality materials is crucial. It ensures durability and longevity of lotion pumps. We inspect various materials like plastic components, springs, and gaskets.

Plastic Components: Checked for durability and consistency.

Springs: Ensure they are resilient and corrosion-resistant.

Gaskets: Inspected for flexibility and sealing capability.

Functional Testing

Functional testing examines the pump's operation. It ensures smooth and even lotion dispensing. We also detect leaks or defects during this phase.

Operation Test: Ensures the pump works smoothly.

Dispensing Test: Confirms even distribution of lotion.

Leak Detection: Identifies any leaks or defects in the mechanism.

Performance Testing

Performance testing ensures the pump meets client requirements. It verifies accurate lotion dispensing and prevents clogging.

Client Compliance: Ensures the pump meets specific client needs.

Accurate Dispensing: Tests the exact amount of lotion dispensed.

Clogging Prevention: Checks for issues that could affect performance.

| Test Type | Purpose | Key Elements |

| Material Inspection | Ensures high-quality materials | Plastic, springs, gaskets |

| Functional Testing | Verifies smooth operation and no leaks | Operation, dispensing, leak detection |

| Performance Testing | Confirms compliance, accuracy, and no clogs | Client needs, accurate dispensing, clog prevention |

Specific Tests and Procedures

To ensure the quality and performance of cosmetic lotion pumps, manufacturers conduct a series of specific tests and procedures. Let's explore some of these essential assessments in detail.

Tightness Testing

Tightness testing ensures no leaks at the thread, pump core, and pump nozzle. This is vital for maintaining product integrity. A proper seal prevents contamination and waste.

Thread Seal: Ensures no leaks at the bottle's neck.

Pump Core Seal: Prevents leaks from the pump's interior.

Nozzle Seal: Ensures no leaks at the dispensing point.

Number of Sprays Test

This test measures the number of sprays required to dispense lotion. Consistency is key. Reliable performance ensures customer satisfaction and efficient product use.

Pump Output Test

Determining the amount of lotion dispensed per pump is crucial. This test ensures uniform and stable output. It helps maintain product consistency.

Compatibility Testing

Ensuring compatibility between the pump and bottle is essential. This test checks for smooth rotation, no detachment, or sliding.

Smooth Rotation: Ensures the pump fits well and rotates smoothly.

No Detachment: Checks if the pump stays securely attached.

No Sliding: Ensures a firm, stable fit.

Pump Suction Port and Length Test

This test ensures the appropriate length and angle of the suction tube. It avoids incomplete or interrupted pumping.

Pump Resilience (Rebound Time) Test

Measuring the time required for the pump to return to its original position is crucial. It ensures quick and reliable pump action.

Drop Test

The drop test ensures durability and integrity after drops. Maintaining sealing and usability after impacts is critical.

Heat and Cold Resistance Test

This test assesses performance under extreme temperatures. Ensuring functionality in various environmental conditions is essential.

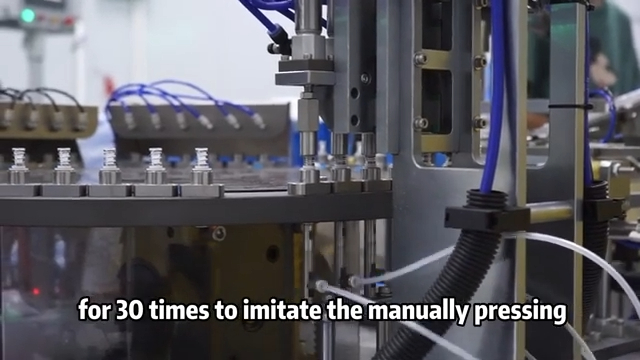

Fatigue Test

The fatigue test checks the pump's durability over multiple uses. Ensuring long-term reliability is key for customer satisfaction.

Mechanical Test Items

This includes testing tightening torque, unscrewing torque, and pull-off force. It ensures mechanical reliability.

Tightening Torque: Ensures proper fitting.

Unscrewing Torque: Checks ease of opening.

Pull-off Force: Measures the force needed to detach parts.

Compatibility Test Items

This test checks the long-term storage impact on pump performance. It includes heat and cold resistance over extended periods.

Cosmetic packaging testing is crucial for ensuring product quality and safety. These tests help manufacturers produce reliable pump and airless pump systems for various cosmetic packaging materials.

| Test Type | Purpose | Key Elements |

| Tightness Testing | Ensures no leaks | Thread, pump core, nozzle seals |

| Number of Sprays Test | Measures spray consistency | Spray count, reliability |

| Pump Output Test | Ensures uniform lotion dispensing | Output measurement, stability |

| Compatibility Testing | Checks pump and bottle compatibility | Smooth rotation, no detachment |

| Pump Suction Port and Length Test | Ensures proper suction tube length | Tube length, angle |

| Pump Resilience (Rebound Time) Test | Tracks rebound time | Rebound time, reliability |

| Drop Test | Ensures durability after impacts | Impact resistance, seal integrity |

| Heat and Cold Resistance Test | Tests performance in extreme temps | Heat and cold resistance |

| Fatigue Test | Checks long-term durability | Durability, long-term performance |

| Mechanical Test Items | Ensures mechanical reliability | Tightening, unscrewing, pull-off |

| Compatibility Test Items | Tests long-term storage impact | Long-term storage, extended resistance |

Supplementary Test Methods

Foam Pump Density and Delicacy

Ensuring high-quality foam output is crucial. A foam pump mixes lotion with air. The result should be dense and delicate foam. We use specific tests to check the foam quality.

| Test Aspect | Purpose | Key Measurements |

| Foam Density | Ensures rich, thick foam | Density level |

| Foam Delicacy | Checks for softness and fineness | Texture assessment |

Spray Pump Atomization Effect

Spray pumps need to deliver a consistent and even mist. We assess the spray consistency and distribution to ensure high performance.

Consistency Test: Ensures each spray is the same.

Distribution Test: Checks how evenly the spray covers an area. We also test the spray angle and distance. This ensures the spray reaches the desired area effectively.

Spray Angle: Measures the angle of the spray.

Spray Distance: Ensures the spray reaches the target distance.

| Test Aspect | Purpose | Key Measurements |

| Consistency | Ensures uniform sprays | Spray uniformity |

| Distribution | Checks even coverage | Coverage area |

| Spray Angle | Measures angle of spray | Angle in degrees |

| Spray Distance | Ensures effective reach | Distance in inches |

These tests are part of the comprehensive cosmetic packaging testing process, which is crucial for ensuring the quality and performance of various cosmetic packaging materials.

Final Thought

Prioritizing core test items is crucial. It ensures the reliability of cosmetic lotion pumps. Determining qualification standards based on specific needs helps in achieving optimal performance. Functional testing is vital. It guarantees the quality and usability of lotion pumps. These tests ensure every pump meets high standards.